Review Quiz Week 3 & 4 - FW Control Systems & Rigging

Flight Control Systems & Rigging Quiz

Test your knowledge on flight control systems and rigging with this comprehensive quiz! Cover a variety of topics related to flight controls, cables, pulleys, and more. Perfect for aviation enthusiasts and professionals alike.

Key Features:

- 58 multiple-choice questions

- Covers a wide range of topics

- Ideal for learners and practitioners in the aviation field

What are the names of the 3 elements or sections of any of the Flight Control Systems?

Input, Feedback and Control Surface Sections

Input, Transmitting and Feedback Sections

Rudder, Elevator & Flap Sections

Input, Transmitting & Control Surface Sections

Which type of Control Cable is most widely used for Primary Flight Control Systems

Extra-Flexible

Flexible

Ultra-Flexible

Non-Flexible

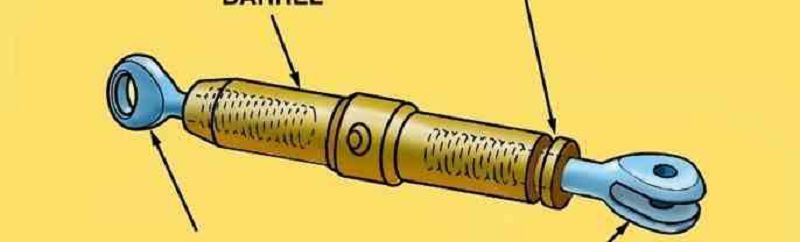

What is the purpose of the groove that is machined into the right hand end of the barrel in this image of the turnbuckle?

It is a crimp that will provide a self-locking function at that end of the barrel

It identifies the end with the left hand threads

Where you complete the initial wrap of lock-wire to safety the turnbuckle

It is a manufacturing mark that is used to hold the barrel in the lathe

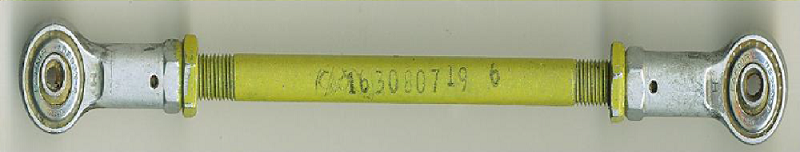

When using the cable tensiometer, what is the purpose of the three different risers 1, 2C & 3 that were used on the tool and identified on the chart

Different cable diameters

Measuring cable runs that are either straight, curved or a combination of the two

Different lengths of cables

Different cable materials

What is the device that is designed to change the direction of a cable run?

Pressure Seal

Bushing

Pulley

Fairlead

When you are inspecting a Pulley and you find that the pattern of the cable has been pressed into the groove of the pulley, what does this indicate?

The cable tension was too high

The pulley has seized or is stuck/frozen

The pulley was misaligned

Nothing, that is normal wear

What is the purpose of a Fairlead?

To protect a cable where it passes close to a structure

Change the direction of a control cable

To prevent pressurization air from leaking through the hole that a cable passes through between the cabin and the wing

To help the control system start to move before the control surface moves

When looking at the basic general aviation three cabled control system what is the name of the cable that runs from the right hand aileron bell-crank all the way over to the left hand aileron bell-crank?

Carry-thru or Balance Cable

Pass-over Cable

Indirect Cable

Direct Cable

What is the purpose of the small hole drilled in the body of the spherical rod end assembly in this diagram?

To ensure the rod end is threaded onto the rod far enough

To provide a greasing port for the bearing

It is a hole for lock-wire

It is a hole for a cotter pin

Which device is used to join and adjust the tension of two flight control cables?

Cable system bellcrank

Turnbuckle assembly

For & Eye cable terminal end

Cable control or push/pull rod

When you turn the control wheel to the right and left, which components are you moving within the aircraft?

The bell-cranks inside each wing outboard of the flaps and the ailerons

The bell-cranks inside each wing outboard of the flaps and the elevators

The bell-crank that is attached to the aft side of the horizontal stabilizer and the ailerons

The bell-crank that is attached to the aft side of the horizontal stabilizer and the elevator

What is the purpose of a Pulley Guard?

To limit the wobbling of the pulley on the attaching fixture

To prevent the cable from jumping off the pulley

To help align the pulley on the cable

To protect the pulley from being damaged

What is the name of the device in this picture used to convert the movement of a Trim Tab cable and chain system to a linear motion to move a push/pull rod attached to the tab?

Screw-jack Assembly

Control Quadrant

Torque Tube Assembly

Bell-crank Assembly

When you are inspecting a pulley and you find a flat spot worn into on spot on the groove of the pulley as shown below, what does this indicate about the pulley?

Frozen or seized pulley

Misaligned Pulley

Misaligned cable

Excessive cable tension

What is the purpose of moving the control wheel to the right or left?

To yaw the aircraft to the right or left

To turn the nose wheel to the right or left

To pitch the aircraft to the right or the left

To roll the aircraft to the right or the left

Which of the following is not a purpose of the floor-mounted pedals in from of the pilot?

Brake actuation

Nose wheel steering

Rudder control

Increase engine power

What is the purpose of pushing the control column forward?

Deflect the elevator to pitch the nose of the aircraft up

Deflect the rudder to pitch the nose of the aircraft down

Deflect the elevator to pitch the nose of the aircraft down

Deflect the ailerons to roll the nose of the aircraft down

What is a common use for Non-flexible 1X7 or 1X19 control cables?

Rudder system controls

Trim Tab system controls

Aileron system controls

Engine controls

What is a common use for 1/8" diameter extra-flexible 7X19 control cables?

Primary flight controls

Secondary flight controls

Environmental system controls

Engine controls

What is the main purpose of rubbing a rag along a cable run during an annual inspection?

To ensure that there are no kinks

To ensure there are no sections of popped core

To check for broken wire strands

To check for worn wire strands

When swaging a terminal end on a cable, once completed, how do you ensure a properly installed swaged-type terminal end?

Using a "Go-No Go Gauge" to measure dimensions

Complete a pull test on the terminal end to ensure crimp

The use of the proper swaging tool ensures correct installation

We do not swage ends onto cables

When installing a Nicopress cable sleeve on a 1/8th inch diameter cable, how many compressions are on the sleeve?

1

2

3

4

In accordance with AC 43:13-1B, when is there enough wear on a cable to require replacement of the cable assembly?

When there are any wear marks at all on individual strands of the cable

Once there is greater than 60% wear on an individual wire

Once there is 40% to 50% wear on individual wire strands

Once there is 40% to 50% wear on an individual wire bundle

Which method of securing a turnbuckle prevents any rotation or twisting of the barrel once installed?

Neither

Both

Lockwire

Locking clip

What is the maximum number of exposed threads on the cable end allowed outside of the turnbuckle end when tensioning a cable system?

2

3

4

5

When using the single wrap 0.040 lock-wire method for safetying a turnbuckle assembly, what is the minimum number of wraps at each end?

2

3

4

5

What is the purpose of the Pulley Guard?

To protect the pulley from damage

To protect the cable from damage

To replace a standard pulley in an extreme environment

To prevent the cable from falling out of the groove

Why is it important to rotate pulleys that only turn through a small arc during an inspection?

To make sure they do not turn too much

To provide a new bearing surface for the cable

To make sure there is enough resistance to rotation to prevent excessive vibration

This is not a practice during inspection

What is the issue if I can see the pattern of the cable over the entire surface of the pulley groove?

Excessive cable tension

No issue that is normal wear

Pulley misaligned

A frozen or seized pulley bearing

What is the purpose of the cable tensioner within the flight control system?

To allow for decreased cable tensions for higher control surface loads

To allow for increased cable tensions for lower control surface loads

To maintain cable tension during long term exposures to various outside air temperatures

To allow for increased cable tensions for higher control surface loads

When adjusting the length of a "Push/Pull or Control Rod" assembly, how do you know that there is enough thread engagement inside of the rod end assembly?

Measure the length of the exposed threads on the rod assembly

Make certain that you can pass a piece of lockwire through the "witness hole" drilled into the rod end assembly

Make certain that you can not pass a piece of lockwire through the "witness hole" drilled into the rod end assembly

Make certain that you are able to apply the proper torque to the jam nut without damaging the threads of the rod end assembly

Which of the following statements about fairleads and rub strips is not correct?

They can be made of phenolic or plastic

They can change the cable direction up to a maximum of 15 degrees

The guide the cable to prevent wear

They help to prevent cable vibration

What device limits the control system travel at the output end of the system?

Limiters

Bellcrank blocks

Primary stops

Secondary stops

What device limits the control system travel at the input end of the system?

Limiters

Bellcrank blocks

Primary stops

Secondary stops

What are the components of the Cessna Aileron Control System reviewed in class?

Two direct cables, one carry-thru cable, one bellcrank and one push-pull tube in each wing

Two carry thru cables, one direct cable, one bellcrank and one push-pull tube in each wing

Two direct cables, one carry-thru cable, two bellcranks and one push-pull tube in each wing

Two direct cables, one carry-thru cable, one bellcrank and two push-pull tubes in each wing

What is the purpose of the down spring system used in the elevator system discussed?

To provide the pilot with control system artificial feel or feedback when moving the control column

To assist the pilot to maintain a nose down attitude

To assist the pilot returning the elevator from an upward trailing edge deflection to neutral position

To assist the pilot returning the elevator from a downward trailing edge deflection to neutral position

On the small aircraft flap systems discussed, what controls the operation of the motor system moving the flap drive system?

Micro-switches

Angle of attack indicator

Sequence valves

Relay assemblies

What is the pivot point for a trimmable horizontal stabilizer (THS) system?

Leading edge or forward attach point of the horizontal stabilizer

Trailing edge or rear attach point of the horizontal stabilizer

Elevator hinge point

Elevator Trim tab hinge

Where will you find the travel limitations for the deflection limits for a given aircraft (how far in each direction)?

In the Aircraft Illustrated Parts Catalog (IPC)

In the Aircraft Type Certificate Data Sheet

In the AC 43:13-1B, 2A Acceptable Practices Techniques & Practices Manual

In the Pilot's Operating Handbook

In the Control Rigging Basic Information, what is supposed to be the most current and up to date status?

The instructions for the use of the Tensiometer

The instructions for the use of the Digital Protractor

The Manufacturer's Technical Publications

The aircraft Certificate of Registration & Certificate of Airworthiness

What was the common purpose of all of the rigging pins and rigging tools discussed during the slides relating to both the generic and the Cessna and Piper rigging processes?

Lock the control system components in full up deflection position

Lock the control system components in full down deflection position

Lock the control system components in the neutral position

There was no specific purpose discussed

According to the Generic Flight Control Rigging Process, what is the first step to accomplishing the rigging of the control system

Adjust the cable tension to limits

Synchronize and neutralize the Control Input

Adjust the position of the bellcrank out in front of the control surface to position the bellcrank in neutral

Adjust the Primary Stops to limit surface travel

As outlined in the Generic Rigging Process, what is the final or last step to accomplishing the rigging of the control system?

Adjust the cable tension to limits

Synchronize and neutralize the Control Input

Adjust the position of the bellcrank out in front of the control surface to position the bellcrank in neutral

Adjust the Primary Stops to limit surface travel

How is the rigging of the flight Control System certified on an aircraft in Canada?

Maintenance Release

Return to Service

Authorized Release Certificate

Airworthiness Release

When referring to the four elements of the Dual or Independent Inspection, which of the following best describes the term "Fit"?

All control surface deflection travels are within the limits specified

All items disconnected or disassembled have been assembled properly, have the correct tension and clearances

Locking devices have been installed correctly and are secure

Control surface movement direction is correct as it relates to control input movement

When referring to the four elements of the Dual or Independent Inspection, which of the following best describes the term "Sense of Motion"?

Locking devices have been installed correctly and are secure

All items disconnected or disassembled have been assembled properly, have the correct tension and clearances

Control surface movement direction is correct as it relates to control input movement

All control surface deflection travels are within the limits specified

When referring to the four elements of the Dual or Independent Inspection, which of the following best describes the term "Range of Motion"?

All control surface deflection travels are within the limits specified

Locking devices have been installed correctly and are secure

Control surface movement direction is correct as it relates to control input movement

All items disconnected or disassembled have been assembled properly, have the correct tension and clearances

When you are checking aileron control surface travel, what position should it be in to start the process?

Full up

Full down

Neutral

Control Wheel all the way back

According to the generic Rigging Instructions, what can be done if there is the correct amount of control travel in one direction but too much travel in the other direction during the control travel check?

Adjust one of the primary control stops

Adjust the cable tension

Synchronize the control input again

Adjust one of the secondary control stops under the instrument panel

According to the final step of the Generic Rigging Instructions what can be done if we have too much control surface travel in one direction and correct in the other direction during our surface travel check?

Adjust one of the primary control stops

Adjust one of the secondary control stops

Synchronize the control input

No action, there is nothing left once you have set the cable tension

In accordance with the generic and the fixed and rotary wing aircraft type specific rigging instructions discussed in class, during the adjustment of the control system which of the following tasks is carried out first?

Synchronize and neutralize the control wheels or input

Adjust the primary control stops

Adjust cable tensions

Neutralized the bell-cranks in front of the ailerons

During the rigging of the transmitting system, how do you ensure that the bellcranks and the control wheel assemblies remain in the neutral position?

Adjust each item only a little at a time

Have someone hold the control wheel

Install locking pins or locking fixtures

Use clothes peg clamps and "Vise Grips" to hold neutral position

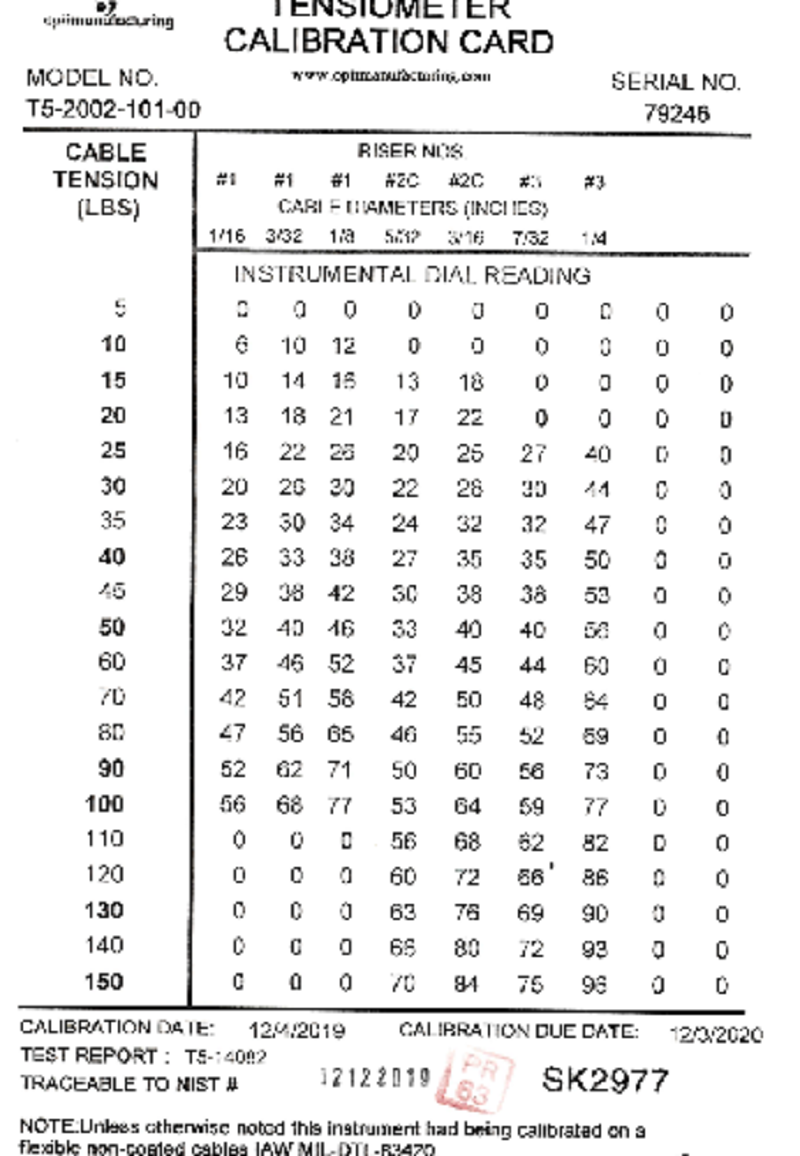

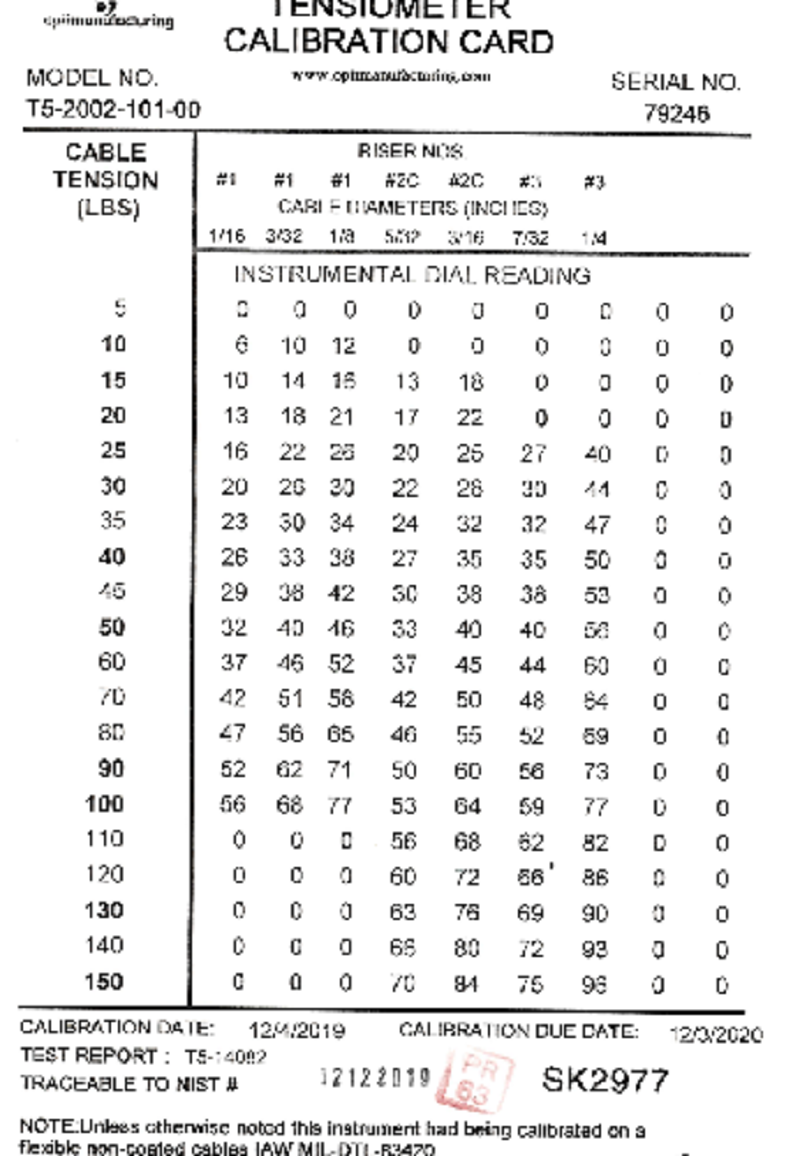

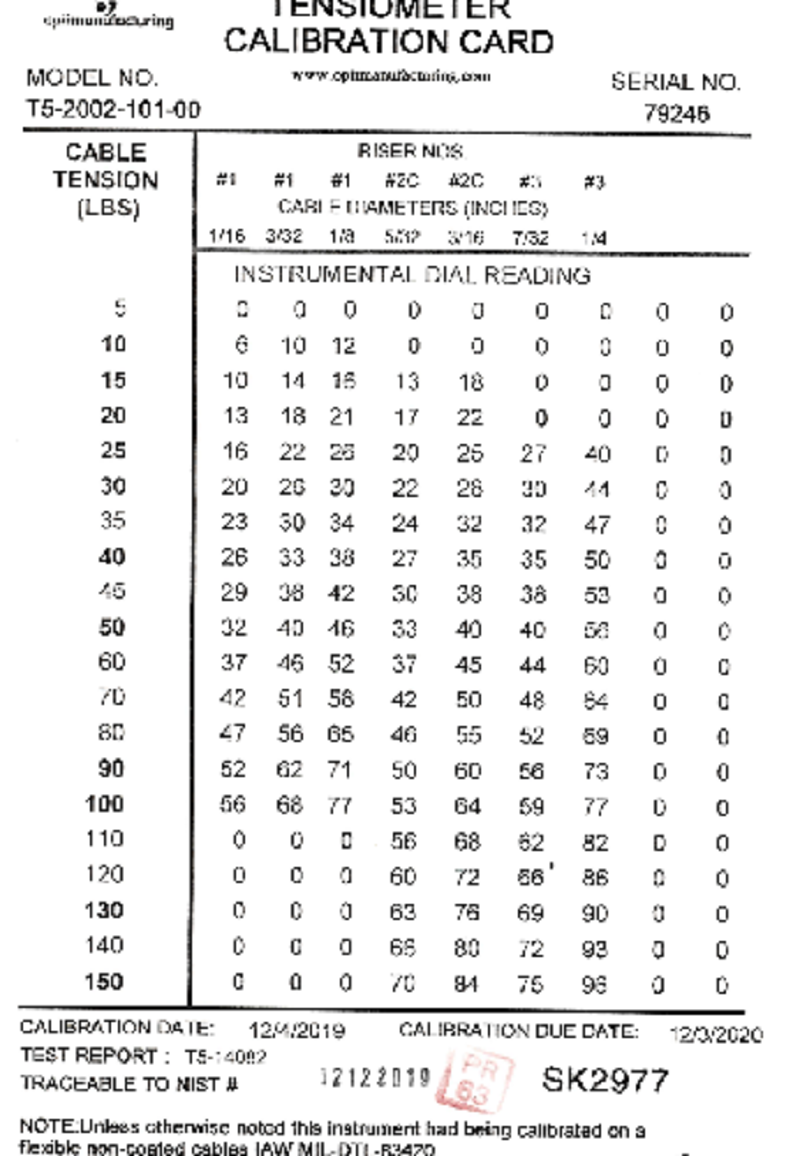

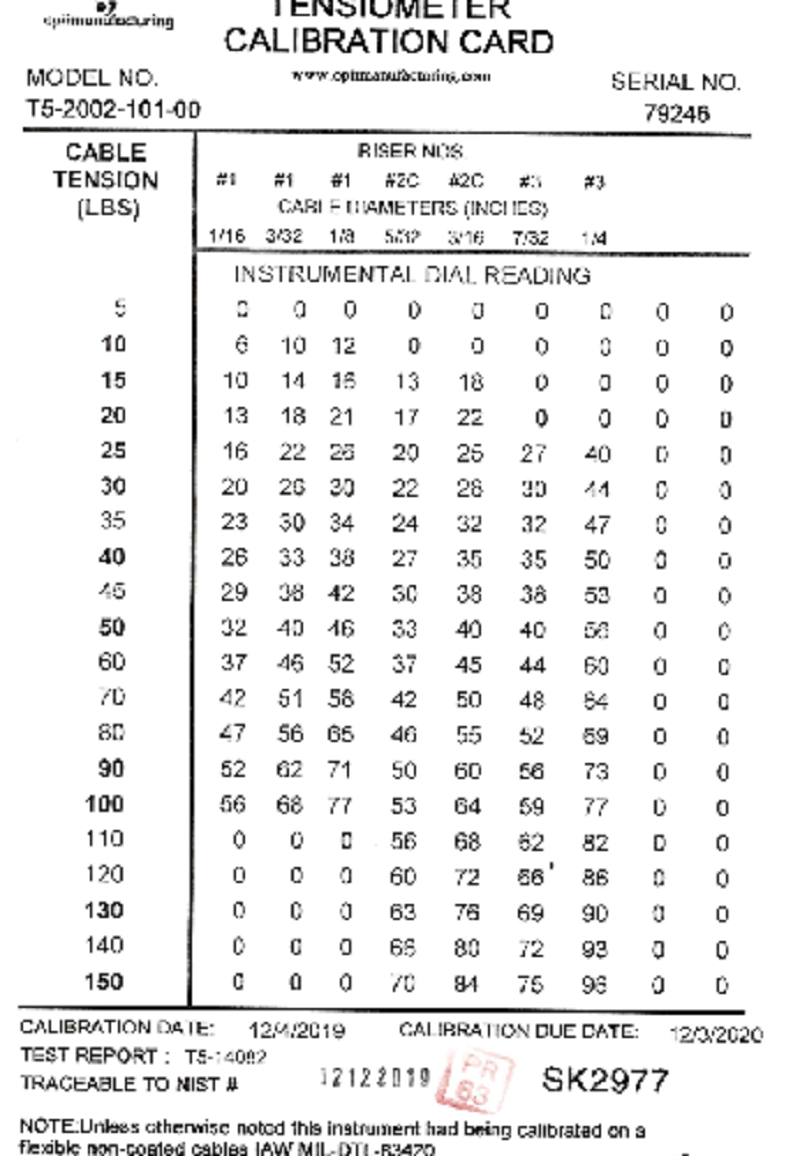

Using the tensiometer Calibration Sheet attached, what size of Riser will you use for a 5/32 inch cable diameter?

Any

#1

#2C

#3

Using the tensiometer Calibration Sheet attached, what size of Riser will you use for a 3/32 inch cable diameter?

#1

#2C

#3

Any of the risers

Using the Tensiometer Calibration Card Attached, What would be the actual tension of a 3/32" diameter cable if the tensiometer needle reads 30?

26 pounds

35 pounds

30 pounds

45 pounds

Using the Tensiometer Calibration Card attached, what would be the tensiometer needle read if the actual tension required was 10 pounds for a 1/16" diameter?

Reading of 0

Reading of 6

Reading of 10

Reading of 15

Using the Tensiometer Calibration Card attached, what would be the tensiometer needle read if the actual tension required was 40 pounds for a 1/8" diameter?

Needle reeds 50

Needle reeds 40

Needle reeds 38

Needle reeds 27

Using the Tensiometer Calibration Card attached, which of the following cable diameters will not have a tensiometer needle reading of 40 for an actual tension of 50 pounds of tension?

3/32" diameter

1/8" diameter

3/16" diameter

7/32" diameter

{"name":"Review Quiz Week 3 & 4 - FW Control Systems & Rigging", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"Test your knowledge on flight control systems and rigging with this comprehensive quiz! Cover a variety of topics related to flight controls, cables, pulleys, and more. Perfect for aviation enthusiasts and professionals alike.Key Features:58 multiple-choice questionsCovers a wide range of topicsIdeal for learners and practitioners in the aviation field","img":"https:/images/course7.png"}

More Quizzes

Airframe Fam

18935

756 Systems Flight Controls

1261022

Ica test

11644

What is your spirt animal

10524

Interactive Caregiving - Home Healthcare Orientation

201016102

Intuition Test - How Intuitive Are You? Free Online

201017322

Piano Notes for Beginners - Free Basics Test

201018074

Company Law - Test Your Knowledge of the Companies Act

201016947

Free Shipping - Test Your E-Commerce Knowledge

201016886

BV or Yeast Infection - Symptom Checker (Free)

201016594

Should I Ask Her Out - Decide with Confidence

201018924

80s Cartoon Trivia - Test Your Retro Knowledge

201022297