Piston2-W.6A

Which of the following is considered Line Maintenance? #5

Engine Adjustments

Vertical Fin Spar Repair

Engine Gear Inspection

Engine crankcase repair

Which of the following is considered Line Maintenance? #2

Periodic Inspection

Engine Crankshaft Inspection

Engine Overhaul

Airframe Structure Repair

Which of the following is considered Line Maintenance? #6

Engine Gear Inspection

Vertical Fin Spar Repair

Engine Crankcase Repair

Engine Oil Servicing

Which of the following is considered Line Maintenance? #3

Airframe Structure Repair

Engine Overhaul

Engine Crankshaft Inspection

Component Replacement

Which of the following is considered Line Maintenance? #1

Troubleshooting

Engine Overhaul

Airframe Structural Repair

Engine bulk inspection

Which of the following is considered Line Maintenance? #4

Engine Cylinder Repair

Engine Camshaft Repair

Operational Checks

Wing Spar Repair

If when troubleshooting a problem you find everything you have checked is working fine, what should you do?

Back up 3 steps and try again, must've done something wrong

Tell your crew chief you cannot do the job

Keep looking, in places that you have not checked yet

Re-do all the test, must have dome something wrong

What information is needed to troubleshoot a problem?

Power setting, climb, level, decent

All of the other answers

Was it a sudden or was it a gradual deterioration

Altitude, temperature, condition, aircraft parameters (power setting, climb, level, decent)

What is troubleshooting?

A "gut reaction" process to determine what is operating normally and where there is a failure occurring

A systematic process to determine what is operating normally and where there is a pilot involved

A systematic process to determine what is operating normally and where there is a failure occurring

A random process to determine what is operating normally and where there is a failure occurring

Once you have identified the "cold cylinder", what will be inspected next?

All the other answers

Inspect for leaks in induction system

Inspect for improper adjustment of the valves

Inspect for faulty leads

Inspect for bad spark plugs

What test is used to identify where rough engine operation is coming from?

Cold cylinder test

Hot cylinder Test

Idle magneto drop test

Idle mixture test

What reference material will help in troubleshooting problems?

Troubleshooting charts in the TC

Troubleshooting charts in the MM

Trouble shooting charts in the STC

Trouble shooting charts in the IPC

What normally causes backfiring?

Excessively rich mixture, that reignites in the intake air once it has been added through leaks in the system

Excessively lean mixture, leading to slow burning air/fuel burning into the ignition into the exhaust manifold

Excessively lean mixture, leading to slow burning air/fuel burning back into and igniting in the intake manifold

Excessively rich mixture, that reignites in the exhaust once air has been added through leaks in the system

What can cause rough engine operation?

Excessive magneto drop

All of the other answers

Improper valve clearance

High manifold pressure

Which of the following would be done as part of a pre-flight inspection? #1

All of the other answerss

Magneto switch "off and open top cowl

Check p-leads and ignition harness for security and position

Start at back of engine check fluid lines for condition, security and leaks

Check bottom cowl for evidence of fuel and oil leaks

Check engine wires harness for condition, loose wires, chaffing, burns and broken insulation

What will be done during a 100 hr inspection?

A detailed engine inspection

The 50 hr inspection

All of the other answers

All recurring AD's

A magneto timing check

Servicing and Lubrication

Compression Test

Spark Plug Cleaning

Internal inspection of the turbocharger compressor and turbine

What will be done during 50 hr inspection?

All of the other answers

Inspect the condition and security of magnetos (external), wiring harness, ignition lead, security and condition

Inspection of cylinders for general condition, evidence of damage, overheating and security

Visual Inspection for condition, security, leaks and damage

Inspection of cylinder cooling fins, baffles and oil cooler for security, condition and cleanliness

Inspect turbocharger & controllers externally for condition, security, leakage and lubricate waste gate with "mouse milk" penetrating oil

Inspect the condition and security of all plumbing lines, hoses and components, control travels, system leaks and servicing of fuel strainer and control device

Drain and change oil (sample if required) replace filter and/or clean screens, condition and security of all plumbing

Which of the following would be done as part of pre-flight inspection? #2

General look over engine for leaks

Look over exhaust risers for blown gasket, missing hardware and leaks

Check propeller for nicks & scratches, and if possible mount hardware for condition and safety devices

Check intake filter and Carburetor/Throttle body for condition and security

Take fuel sample and look for water contamination

Check engine baffling for cracks, damaged or missing seals as this could lead to overheating

All of the other answers

What typical things will be checked during a ground run?

Oil pressure

All of the other answers

Idle RPM

Live magneto check

Propeller and governor operation

Max static RPM

Carb heat/Alternate air

Ancillary system operation

Post maintenance, what SHOULD be done to prepare for ground runs?

All of the other answers

Install engine cowls and rig cowl flaps as required

Pre-oiling the engine may be required to ensure that all parts have oil prior to engine start

Fuel system leak check should be caried out to ensure against leaks

Post maintenance what MUST done before a round run?

Secure the aircraft as needed (chocks/tie down)

All of the other answers

Carry out a walk around

Check the aircraft for damage and condition

Inspect ramp for debris

Check fluids, remove any plug/covers/control locks

How much should the engine RPM change when turning on Carb heat?

Up 50-70RPM

Up 150-200 RPM

Down 50-75 RPM

Down 150-200 RPM

What precautions must be taken when ground running turbocharged engines?

Oil temp must be 2/3 of green arc before full power checks

Alternate air must be closed

All of the other answers

When possible have 2 people in the cockpit/ 1 to run and 1 to record things

Allow for 5 minute cool down at 1000RPM before shutting down engines

Advance throttle slowly and steadily

Before starting the aircraft what should you do?

All of the other answers

Call out "all clear"

Make sure everyone is "all clear"

Review relevant procedures in the POH

At what engine speed(s) should Carb heat be checked?

Idle

Idle and 1200 RPM

Full power

Idle and full power

How long should the first ground run after maintenance be?

Long, with a check for fluid leaks 1 hour afterwards

Brief, with a check for fluid leaks 1 hour afterwards

Brief, with a check for fluid leaks immediately afterwards

Long, with a check for fluid leaks immediately afterwards

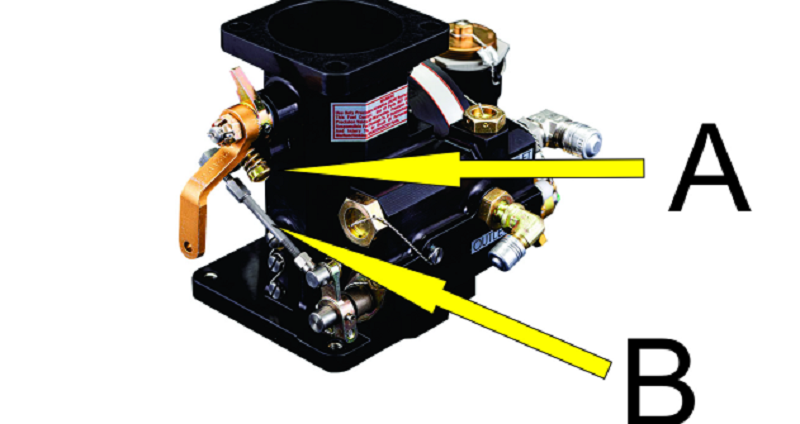

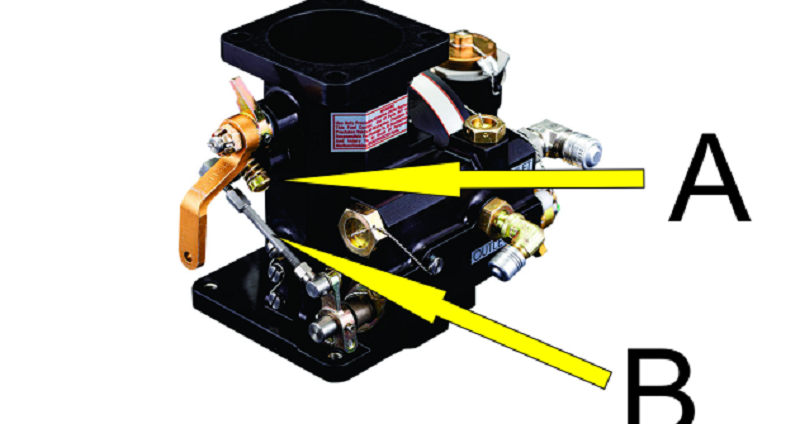

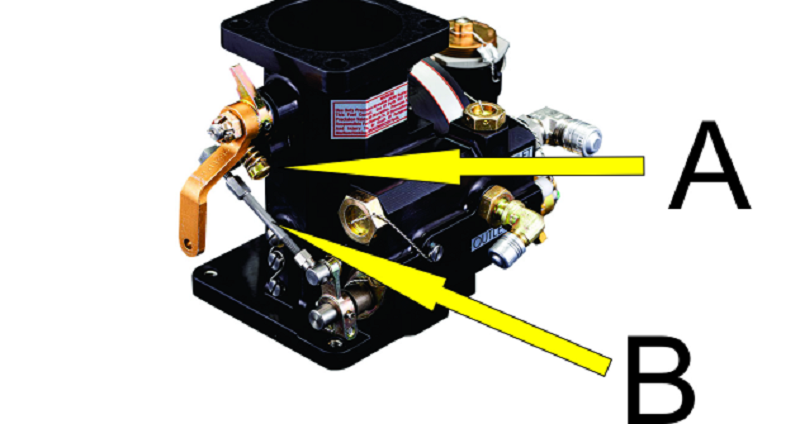

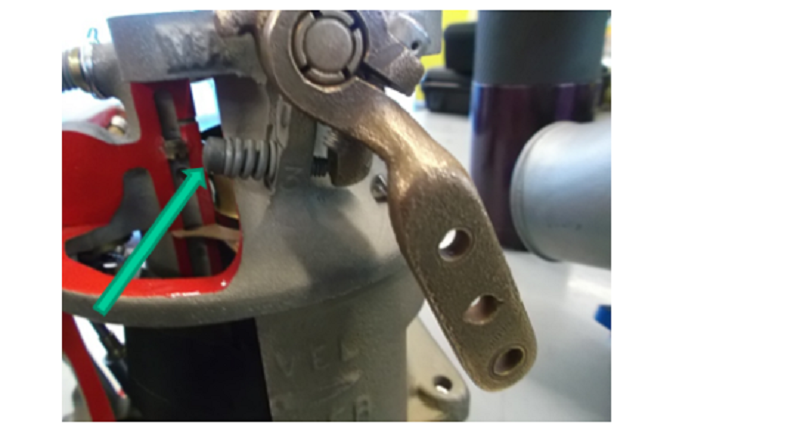

What happens if B is Lenghted?

Idle mixture will richen

Idle speed will decrease

Idle mixture will lean

Idle speed will increase

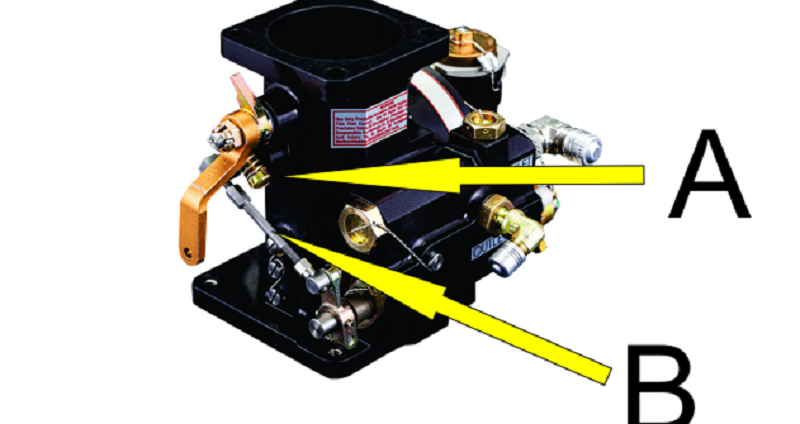

What adjustment is shown in B?

Idle Speed

Maximum Speed

Idle mixture

Fuel pressure

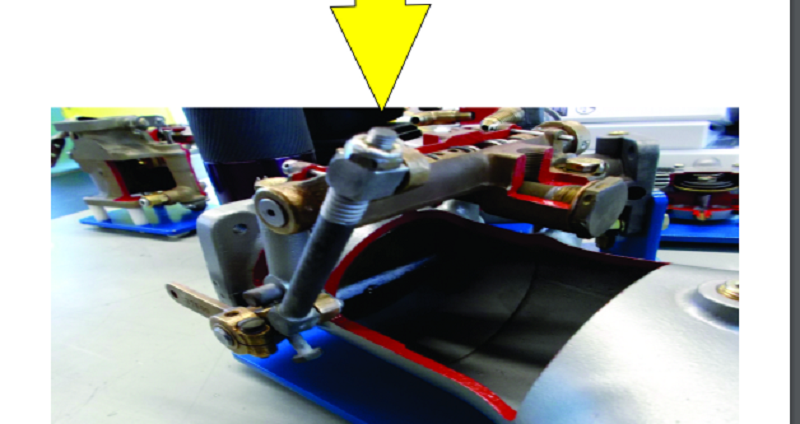

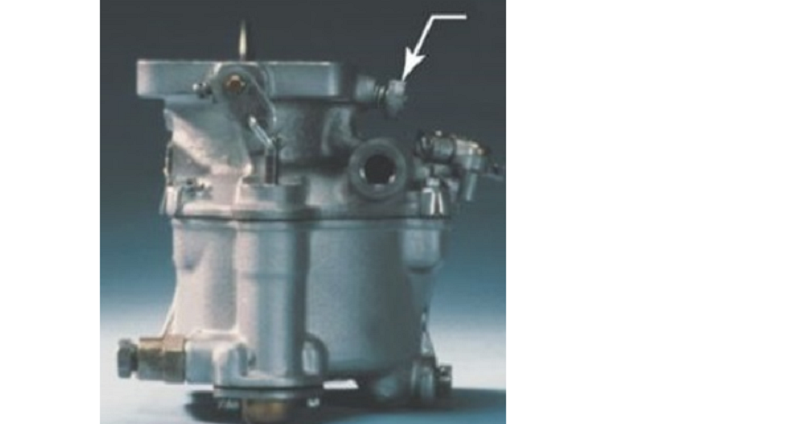

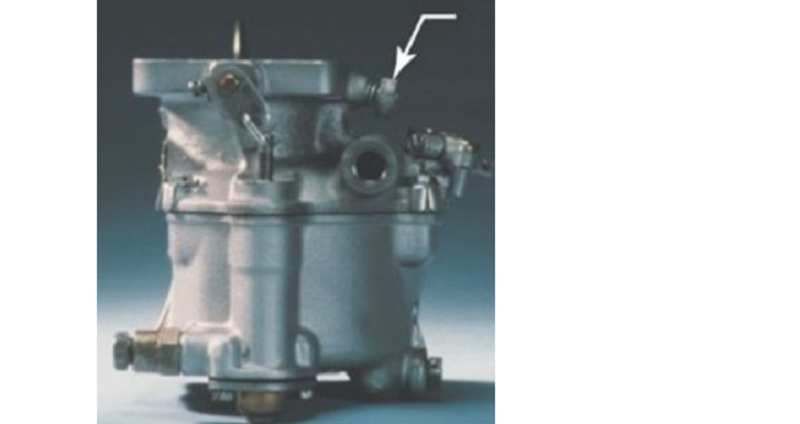

What adjustment is indicated?

Idle speed

Full Speed

Un-metered fuel pressure

Idle mixture

After adjusting the idle mixture what needs to be adjusted next?

Idle speed

Full speed

Upper deck pressure

Full power mixture

What will happen if B is shortened?

Idle speed will increase

Idle mixture will lean

Idle speed will decrease

Idle mixture will richen

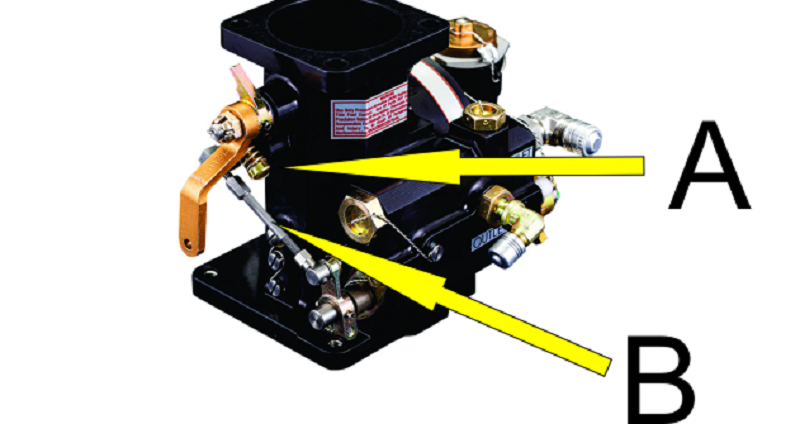

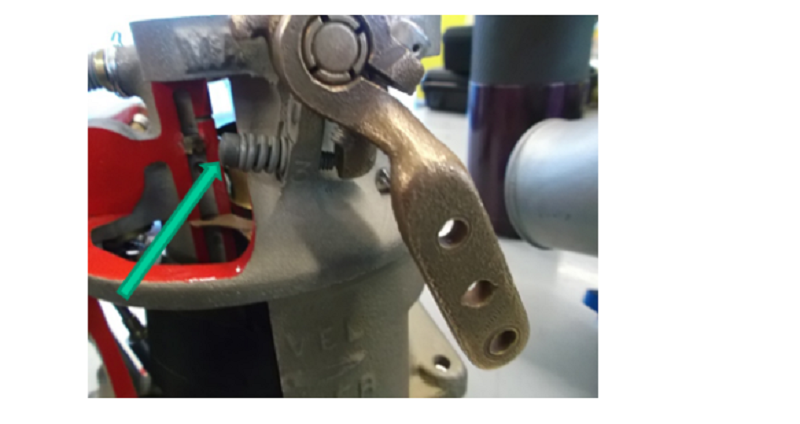

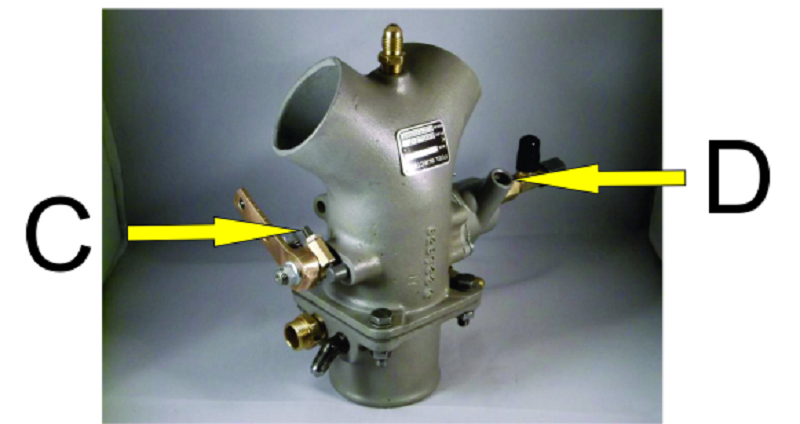

What adjustment is indicated by D?

Full speed

Un-metered fuel pressure

Idle speed

Idle Mixture

If the RPM increases 25-50 RPM, and then the engine stops during an idle mixture check what does that mean?

Mixture is rich

Mixture is correct

Test is invalid

Mixture is lean

What is the correct RPM change for idle mixture?

25-50 RPM decrease

25-50 RPM increase

75-100 RPM decrease

75-100 RPM increase

How often will the float level be adjusted in a carburetor?

Every 100hrs

Annually

At O/H

Every 500 hrs

If the RPM increases by 75-100 RPM and then the engine stops during and idle mixture check what does this mean?

Mixture is correct

Test is invalid

Mixture is lean

Mixture is rich

When will the idle speed adjusted in a carburetor?

After warm up

Every 100 hrs

After cool down

Annually

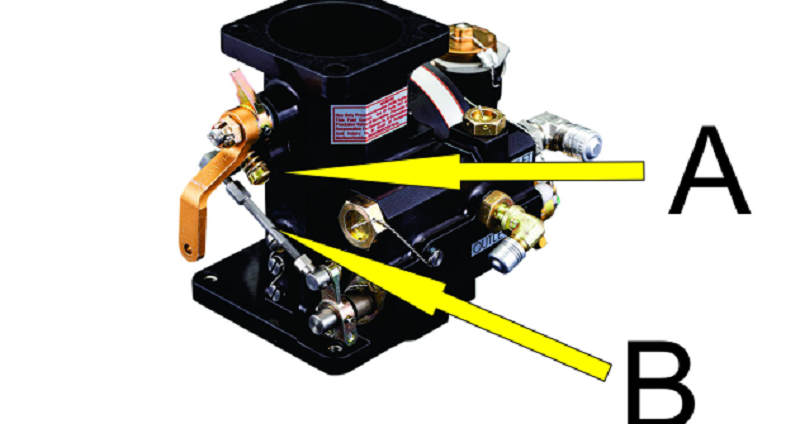

What will happen if A is adjusted in or clockwise?

The idle mixture will lean

The idle speed will increase

The idle mixture will richen

The idle speed will decrease

If the RPM increases in 0-25 RPM and then the engine stops during and idle mixture check what does that mean?

Mixture is correct

Mixture is lean

Test is invalid

Mixture is rich

What will happen if A is adjusted out or counter-clockwise?

Idle speed will decrease

Idle speed will increase

Idle mixture will richen

Idle mixture will lean

What will happen if this screw is adjusted in or clockwise? #2

Idle mixture will richen

Idle speed will decrease

Idle speed will increase

Idle mixture will lean

What will happen if this screw is adjusted out or counter-clockwise? #1

Idle speed will increase

Idle speed will decrease

Idle mixture will lean

Idle mixture will richen

What will happen if this is adjusted in or clockwise? #1

Idle mixture will richen

Idle mixture will lean

Idle speed will decrease

Idle speed will increase

What adjustment is shown at A?

Idle speed

Fuel pressure

Maximum speed

Idle mixture

If the RPM does not rise and the engine stops during an idle mixture check what does that mean?

Mixture is lean

Mixture is rich

Test is invalid

Mixture is correct

What will happen if this screw is adjusted out or counter-clockwise? #2

Idle speed will decrease

Idle mixture will richen

Idle mixture will lean

Idle speed will increase

What adjustment is indicated by C?

Un-metered fuel pressure

Idle mixture

Idle speed

Full speed

How often will the idle speed be adjusted in a carburetor?

Every 100 hrs

Annually

As required

Every 500 hrs

{"name":"Piston2-W.6A", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"Which of the following is considered Line Maintenance? #5, Which of the following is considered Line Maintenance? #2, Which of the following is considered Line Maintenance? #6","img":"https://www.quiz-maker.com/3012/CDN/96-4691566/screenshot-2023-11-30-093322.png?sz=1200-00000026671000005300"}

More Quizzes

Tech Talk(Refresh Our Knowledge)

1057

Prueba

100

Fahrenheit 451 Quiz

630

Quiz or Phanguiz

420

Challenge Yourself: Questions About the Death Penalty

201031433

Family Matters Trivia: Master the Theme Song?

201027233

Grad. Jazz Improv. II

15819933

Free Branding Basic ICEV Final Assessment

201022190

Free Mandatory Reporter Training Knowledge Test

201026446

Free Review: Author Critique of Society

201023224

Discover Your Elm Persona: Freaky Questions

201026446

Free White Blood Cell Review

201028079