Piston II - Week 1 Review

What is lead fouling?

A light tan to light brown coating all over the spark plug

Wet black deposits on the spark plug nose

When deposits connect the center electrode to the ground electrode

Sooty black deposits on the spark plug nose

When inspecting the spark plug after removal wheat are you looking for?

Erosion & wear

Erosion, cracks, leaks & wear

Erosion, leaks & wear

Cracks, leaks & wear

What tools would be used to remove spark plug leads from the spark plugs?

1 wrench

Pliers & screwdriver

Pliers & channel locks

2 wrenches

What would you do with a spark plug with a cracked nose insulator?

Replace it at the next inspection

Replace it before further flight

Nothing, continue using it

Clean it, re-gap and continue service

Who should NEVER test spark plug operation?

Apprentices

Anyone

Anyone with medical condition or implanted medical cardiac devices

Licensed engineers (that's an apprentice job)

What component on a magneto causes the mag to produce a high intensity spark even at very slow rotational speeds?

Impulse coupling

Breaker points

Primary winding

Distributor

How tight should ignition lead "B" nuts be?

80-100 in-lbs + 1/8 turn

Finger tight + 1 turn

80-100 ft-lbs + 1/8 turn

Finger tight + 1/6 turns

What are the steps for cleaning spark plugs?

Grit blast, solvent wash, dry

Remove lead deposits, grit blast, solvent wash, dry, remove residual grit

Solvent wash, dry, remove lead deposits, grit blast, remove residual grit

Remove lead deposits, grit blast, solvent wash, dry,

What tools are used to identify TDC?

The TDC locator and the timing disk

The BDC locator and the timing disk

A screwdriver to remove the plug over the timing gear

A wrench to remove the plug over the timing gear

What is the big risk when installing spark plugs?

Electrical shock

Accidental sparks igniting fuel residue/vapours

Cross threading the cylinder

Cross threading the crankcase

What is the first thing done before doing magneto to engine timing?

Install the timing indicator

Remove all ignition leads

Remove the propeller

Remove all spark plugs

How do you tell if a cylinder is on the compression stroke?

Just look in the spark plug hole for when the piston is travelling upwards in the cylinder

Pressure will "blow" your finger out of the cylinder as the engine is turned in the correct direction

Pressure will "suck" your finger into the cylinder as the engine is turned in the correct direction

No air will flow in or out of the cylinder as the engine is turned

What is a bridged spark plug gap?

When deposits connect the center electrode to the ground electrode

Sooty black deposits on the spark plug nose

Wet black deposits on the spark plug nose

A light tan to light brown coating all over the spark plug

What kind of magneto drives are used?

Directly driven and cable driven

Magnetically driven & rubber bushing driven

Directly driven & rubber bushing driven

In-directly driven & rubber bushing driven

Where will you find instructions for internal magneto timing?

In the engine maintenance manual - in the ignition system section

FAA advisory circular AC43.13A & B

Each magneto manufacturer will have instructions for this process

In the aircraft maintenance manual - in the engines section

Where must the engine be set before installing a magneto?

Cylinder #1 TDC

Cylinder #1 power stroke

Cylinder #1 firing position

Cylinder #1 BDC

When setting e-gap on magnetos without an impulse coupling what must you do?

Set the magneto shaft to the correct position

Ensure the coupling is loaded and stop

Ensure the coupling has released and turn back to the required position

Ensure the coupling is loaded and turn back to the required position

Why should you never move a propeller unless absolutely necessary?

Because you may damage the vacuum pump vanes

Because the engine may fire & start if the "p lead" is grounded

Because the engine may fire & start if the "p lead" is not grounded

Because you may damage the crankshaft due to moving it without lubrication

What is oil fouling?

Wet black deposits on the spark plug nose

When deposits connect the center electrode to the ground electrode

A light tan to light brown coating all over the spark plug

Sooty black deposits on the spark plug nose

What is the purpose of internal magneto timing?

To time the engine to the magneto

To time the magneto to the engine

To adjust the points to open at the best point for the highest energy spark

To adjust the points to close at the best point for the highest energy spark

What should be done after cleaning spark plugs?

Gap, test, install new crush gaskets & install into engine

Install old crush gaskets & install into engine

Test, gap, install new crush gaskets & install into engine

Test, gap, install old crush gaskets & install into engine

What tool will be used to determine if the points on a magneto are open?

Feeler gauge

Timing box

MK1 eyeball

Screwdriver

What tool will be used to determine if the points on a magneto are closed?

Timing box

Feeler gauge

Screwdriver

MK1 eyeball

When setting e-gap on magnetos with an impulse coupling what must you do?

Ensure the coupling is loaded and stop

Ensure the coupling has released and turn back to the required position

Ensure the coupling is loaded and turn back to the required position

Set the magneto shaft to the correct position

How will spark plug installation be started?

By cordless driver

By impact driver

By ratchet

By hand

What is carbon fouling?

When deposits connect the center electrode to the ground electrode

Wet black deposits on the spark plug nose

Sooty black deposits on the spark plug nose

A light tan to light brown coating all over the spark plug

Once a spark plug is cleaned and gapped what should you do with it?

Install it immediately

Protect the end of the plug with a coating of grease

Take care to avoid damage & contamination before installation

Protect the end of the plug with a coating of anti-seize

What must be done if a spark plug is dropped?

Nothing, just install it

It must be re-cleaned, gapped and tested before installation

It must be re-cleaned, gapped, inspected and tested before installation

It must be thrown away

How much wear is allowed to the spark plug electrodes before scrapping?

50%

25%

40%

30%

How can you set the engine to the correct firing position?

Using the #1 blade of the propeller to the starter housing mark

Using the starter pinion gear mark to the starter housing mark

Using the #1 blade of the propeller to the crankcase seam

Through inspection plugs using timing marks on gears

How can you set the engine to the correct firing position? #4

Using the #1 blade of the propeller to the crankcase seam

Using the #1 blade of the propeller to the starter housing mark

Using special tools

Using the starter pinion gear mark to the starter housing mark

What is used to disable magneto ignition systems?

The Q-lead

The I-lead

The P-lead

The power connection to the battery is opened

Where are the timing marks on the Lycoming engine installed on the C172?

On the flywheel & alternator

On the crank flange, starter housing and the crankcase

On the flywheel, starter housing and the crankcase

By removing the inspection plug & looking for the marks on the gears

How many spark plugs do you remove before a compression test?

All

2 per cylinder

3 per cylinder

1 per cylinder

How can you set the engine to the correct firing position? #3

Using the #1 blade of the propeller to the crankcase seam

Using the #1 blade of the propeller to the starter housing mark

Using timing marks on the flywheel & upper case seam

Using the starter pinion gear mark to the starter housing mark

What must be done to prepare a magneto for installation on the engine?

By putting a 10 penny nail through the starter housing into the shaft

Set the timing to cylinder #4 firing position by using a timing pin through the distributor gear

Set the timing to cylinder #1 firing position by using a 10 penny nail through the housing into the magnet drive shaft

By rotating the flywheel until the chamfered tooth is centered in the side window

Where do cylinders typically have leaks during a compression check?

Rings, piston head and cylinder base

Intake valve, cylinder head and exhaust valve

Rings, piston head and cylinder barrel

Rings, intake valve & exhaust valve

What must be done to prepare a magneto for installation on the engine?

By rotating the magneto shaft until the painted chamfered tooth is centered in the window

By putting a 10 penny nail through the starter housing into the shaft

By rotating the flywheel until the painted chamfered tooth is centered in the side window

Set the timing to cylinder #4 firing position by using a timing pin through the distributor gear

What must you do to time both magnetos on an aircraft engine?

Turn the ignition switch to R

Turn the ignition switches to off

Turn the ignition switches to on

Turn the ignition switch to L

Why should you never touch the ignition leads when moving the propeller?

LOW VOLTAGE electrical shock is possible

Nothing will happen

HIGH VOLTAGE electrical shock is possible

High CURRENT electrical shock is possible

How securely should you hold on to the propeller during a differential compression check?

Only lightly

You don't need to hold the propeller

Just tie the prop loosely to the wing tip

As tightly as possible

Once the magneto and the engine are timed correctly what do you do?

Connect the timing light and install the magneto

Remove the timing pin install the magneto and torque the hardware

Install the magneto with torqued hardware and remove the timing pin

Install the magneto with snug hardware and remove the timing pin

How many people does it take to do a differential compression test?

3

4

2

1

How can you set the engine to the correct firing position? #1

Using the starter pinion gear mark to the starter housing mark

Using the #1 blade of the propeller to the crankcase seam

Using the #1 blade of the propeller to the starter housing mark

Using timing marks on the crankshaft flange and the crankcase seam

What must you do to time both magnetos on an aircraft engine?

Ground out the P-Leads

Connect the P-leads from the magnetos

Disconnect the P-leads from the magnetos

Connect the P-Leads to the battery

How is engine to magneto timing adjusted on a horizontally opposed engine?

By changing gear sets

By use of a vernier coupling

By turning the magneto on the accessory housing

By turning the flywheel on the crankshaft

How do you know if you are at TDC in the compression stroke during a differential compression check?

The impulse couplings will have "snapped" 25 degrees earlier

The propeller will only want to move a little bit

The propeller will want to move a lot

The propeller will not want to move

When doing a BDC cylinder leak test what would indicate a leak?

Wavering of the propeller

Burping and knocking from the cylinder

Difficulty in holding the propeller

Bubbles & a hissing sound

What must be done to prepare a magneto for installation on the engine?

By putting a 10 penny nail through the starter housing into the shaft

Set the timing to cylinder #1 firing position by using a timing pin through the distributor gear

Set the timing to cylinder #4 firing position by using a timing pin through the distributor gear

By rotating the flywheel until the chamfered tooth is centered in the side window

Which of the following would indicate excessive Piston Ring leakage?

Hissing sound from the crankcase breather line

Hissing sound from the induction filter

None of the above, piston rings do not leak

Hissing sound from the muffler tail pipe

How much pressure should be applied to the cylinder during a compression test?

29.92 in Hg

80 PSI

70 PSI

80 Bar

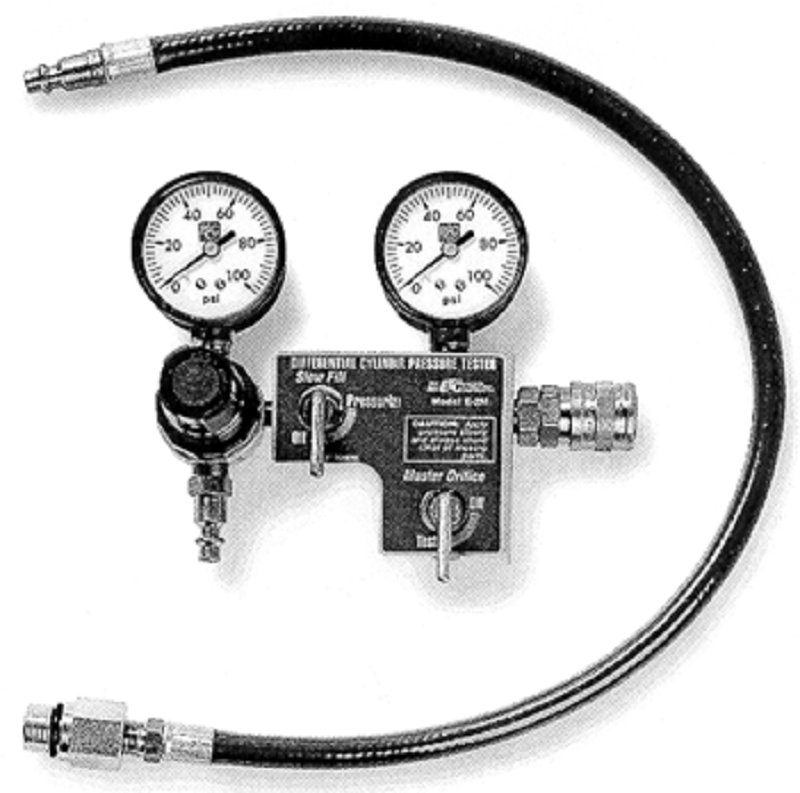

What is this tool?

Differential compression tester

Instantaneous compression tester

Dual altimeter

Hydraulic pressure gauge

How can you set the engine to the correct firing position?

Using the #1 blade of the propeller to the starter housing mark

Using the starter pinion gear mark to the starter housing mark

Using timing marks on the alternator pulley & timing mark plate

Using the #1 blade of the propeller to the crankcase seam

What should you never do when doing a differential compression check?

Stand beside the engine

Stand behind the prop

Stand in or near the prop disk

Stand in front of the prop

Which of the following would indicate excessive exhaust valve leakage?

Hissing sound from the muffler tail pipe

None of the above, piston rings do not leak

Hissing sound from the induction filter

Hissing sound from the crankcase breather line

What will happen if you forget to remove the magneto timing pin?

Trivial damage to the magneto

Severe damage to the engine

Severe damage to the magneto

No damage to the magneto

How do you know that both magnetos have the same timing?

The buzz box lights will change state at the same time

The buzz box lights will flash alternately back and forth

One light on the buzz box will change state before the other

The buzz box lights will not change state

What can happen if the propeller moves freely during a compression check?

Nothing

Minor bruising

Small cuts

Death or severe injury

Which of the following would indicate excessive intake valve leakage?

Hissing sound from the crankcase breather line

Hissing sound from the induction filter

None of the above, piston rings do not leak

Hissing sound from the muffler tail pipe

How do you know when you reach compression stroke during a compression test?

You feel resistance when turning the prop with the compression tester not connected

There is no way to tell if you are in the compression stroke without applying pressure

You feel resistance when turning the prop with the compression tester connected

You will feel the prop begin to "pull" through the stroke by itself

How can you set the engine to the correct firing position?

Using timing marks on the flywheel & starter housing

Using the starter pinion gear mark to the starter housing mark

Using the #1 blade of the propeller to the starter housing mark

Using the #1 blade of the propeller to the crankcase seam

{"name":"Piston II - Week 1 Review", "url":"https://www.quiz-maker.com/QPREVIEW","txt":"What is lead fouling?, When inspecting the spark plug after removal wheat are you looking for?, What tools would be used to remove spark plug leads from the spark plugs?","img":"https://www.quiz-maker.com/3012/CDN/94-4621305/compression-test-gauge.png?sz=1200"}

More Quizzes

Viennese Musical Clock by Kodaly

5269

Social Media Usage Quiz

6340

Physics Class 9 Mock Test

11631

Take this quiz to see what kitchen utensil you are

840

Enzyme Practice Problems - Free Online

201017279

What Kind of Person Am I? - Free & Instant Results

201016451

Which Footballer Are You? Free Personality

201017877

Which YouTuber Are You? Free With Instant Results

201017092

Is He the One - Find Out If He's Right for You

201017947

Zombie Trivia - Test Your Undead Knowledge

201016676

DEI Pre-Assessment - Diversity, Equity & Inclusion

201015976

Mind Reading Test - Are You Telepathic? Free Online

201016451